Maintenance of Rotary Drum Dryer

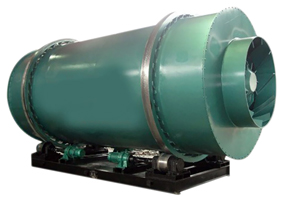

Rotary drum dryer is a common drying equipment for drying materils with the advantages of stable running, being easy to operate, good adaptability and high capacity. It is widely used in  chemical industry, metallurgy and building materials and light industry, etc. It consists of drum, supporting device, driven device and end sealing device. Drum is the base part of the dryer, which transfers heat and mass and deliver materials. The supporting device is composed of rolling ring, riding wheel and catch wheel. Transfer the whole weight of the drum to riding wheel by rolling ring, rolling ring rolls on riding wheel, catch wheel stops drum axis moving. Transmission includes electrical machine, reducer, gear, gear ring, feed-in and feed-out device and sealing device.

chemical industry, metallurgy and building materials and light industry, etc. It consists of drum, supporting device, driven device and end sealing device. Drum is the base part of the dryer, which transfers heat and mass and deliver materials. The supporting device is composed of rolling ring, riding wheel and catch wheel. Transfer the whole weight of the drum to riding wheel by rolling ring, rolling ring rolls on riding wheel, catch wheel stops drum axis moving. Transmission includes electrical machine, reducer, gear, gear ring, feed-in and feed-out device and sealing device.

1.Adjustment of Axis Moving in the Process of Overhaul

According to operating principle and structure features of the dryer and the experience of maintaining in production, the key is adjusting riding wheel for ensure the mechanical equipment safe running in the long term. Preserve linearity of the dryer axis; drum moves to and fro along the axis so that the catch wheel keeps standstill or move lightly in a short time. Each catch wheel and each riding wheel should take up the drum weight together and evenly.

2.Adjustment Method:

Observe whether the relative position of wheel belt and riding wheel is in the middle position or not; situation of catch wheel force and rotate.

Adjust riding wheel according to the rotating direction of drum, adjust the centre line of the riding wheel, make riding wheel skew to a certain direction, form a small drift angle with drum centre line (less than 0.5° to avoid wearing riding wheel)and has a force of push spiral upward, which should be balance with the move force of the drum. Drum running in a relatively stable position, that is, wheel belt moves to and fro freely between the top and bottom riding wheel.

3.Adjustment Steps:

When the drum moves downward, screw down adjustable bolt 2 a round and loose adjustable bolt 1 a round (the screw and the loose number should be the same), then the drum stops moving downward; if it moves upward, add liquid lubricating oil to riding wheel, then the drum stops, if it still moves upward, screw adjustable bolt 1 and loose adjustable bolt 2, then the drum stops moving upward; if it moves downward again, wipe the lubricating oil on the riding wheel, repeat the above way if necessary, until it stops moving. Avoid the riding wheel skew to the different direction in adjustment process.

In the adjustment process, pour some lubricating oil on riding wheel to increase the skin friction to move drum of the dryer upwards; on the contrary, spread some thick lubricating grease to reduce skin friction. Adjust four riding wheels at the same time, and ensure the contact surface between wheel belt and riding wheel is larger than 50%.

4.Applying Effect:

Rotary drum dryer is adjusted by riding wheel, it reduces the force of catch wheel, extends the service life of riding wheel and catch wheel, reduces the cost and increases production efficiency. Meanwhile, lighten the friction losses of riding wheel and wheel belt (rolling ring) and extend equipment service life. Our rotary drum dryer can continuously operate for 4 years without overhaul, but wear and tear is inevitable, so maintain constantly and keep lubricating, check the position of riding wheel and catch wheel and bearing heat condition, adjust or maintain timely to ensure the normal operation.