Tri Drum Dryer

ⅠAdvantages of the GC-HYC Series:

- Our products and services have stretched out to a lot of domestic cities and other countries such as Spain, Canada, Russia and South Korea.

- They are designed to dry sawdust, dregs and residues, marigold, jerusalem artichoke dregs, alfalfa, gingko, sliced carrots, stems and leaves of broccoli and mulberry, barks, tea leaves and the like.

- Covering 20,000 square meters with the workshop area of 4,000 square meters, the factory possesses a large annual production capacity of about 50 sets.

- We have an experienced and professional team excelling in installation and commissioning, capable of handling 5 sets for the user.

- Our sophisticated after sale services, high quality products and timely on-scene services are always for you.

ⅡTechnical Parameters:

| Model | GC-HYG-900 | GC-HYG-1800 | GC-HYG-3600 | GC-HYG-5400 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Initial moisture content | 70% | 60% | 55% | 70% | 60% | 55% | 70% | 60% | 55% | 70% | 60% | 55% |

| Final moisture content | 10% | 10% | 10% | 10% | 10% | 10% | 10% | 10% | 10% | 10% | 10% | 10% |

| Dehydrating capacity (kg/h) | 900 | 1800 | 3600 | 5400 | ||||||||

| Yield (kg/h) | 450 | 720 | 900 | 900 | 1440 | 1800 | 1800 | 2880 | 3600 | 2700 | 4320 | 5400 |

| Coal consumption( kg/t) | 400 | 250 | 200 | 400 | 250 | 200 | 400 | 250 | 200 | 400 | 250 | 200 |

| Power consumption (kw/h) | 27 | 40.8 | 60 | 76.8 | ||||||||

| Installed capacity(kw) | 45 | 68 | 100 | 128 | ||||||||

| Dimension: L(m) × W(m) × H(m) | 24 × 8 × 7 | 28 × 9 × 8 | 32 × 10 × 9 | 36 × 12 × 10 | ||||||||

The utility of the GC-HYC series covers a wide range of material process and the machineries have been offering satisfactory services for our customers.

- The series are generally composed of 7 systems 20 machine units, automatically controlled and closed type running during the entire process.

1.drying drum 2. conveying system 3. airheater system 4. discharge system 5. air induction system 6. electric control system 7. safety system

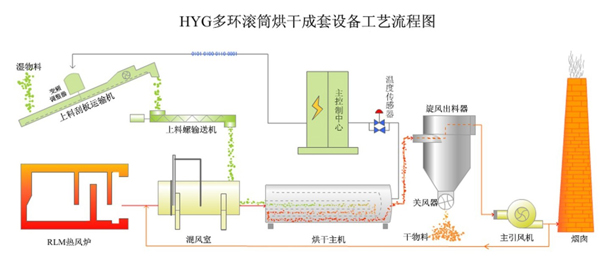

Ⅲ Process Flow Diagram of the HYG Multi-Circle Drum Dryer Complete Set

1.Moist material 2.frequency conveter 3.drag conveyer 4.screw conveyer 5. electric control system 6. moisture sensor 7. RLM airheater 8. mixed air drum9. drying drum 10. dried material 11. air lock 12. cyclone discharger 13. big induced fan 14. funnel

Ⅳ Features

1. Fast Drying Speed and High Efficiency

It adopts a three layer drum set equipped with special shovelling plates. Specifically, thanks to the plates work, feedstock and the hot air will get blended in a dynamic status, with the heat capacity coefficient of 300——500cal/m2hco. The new technology of drying in high temperature and high humidity can also enhance the coefficient of heat transmission, resulting in producing 5 tons dried material per hour to the uttermost.2. Energy Saving and Low Costs

The complete set is capable of self control automatically and continuously during the operation, also characteristic of high thermal efficiency. The adoption of advanced technology of quasi-overheating steam status can be conducive to saving energy of 15%---20%. Fuel for the airheater covers oil, gas and coal. And the dryer taking coal as the fuel will consume about 150kg---500kg for per ton dried material.

3. Supreme Quality

The speed-regulating conveyer can help to even material loading capacity. Proportional control burner takes gas and oil as the fuel while the fuzzy control one takes coal as the fuel, during which the temperature can be automatically controlled so that neither the drying efficiency nor the material ingredients will be adversely affected.

4. Safe Process and Friendly Working Environment

Of the pipeline, explosion discharge system and auto-fire extinguishing system secure a reliable working environment; negative pressure control system through the entire line can keep dust and noise away.